KYEC has developed very cost-effective services for MEMS ICs by using its self-built high parallel testing solutions. It provides customers with various test solutions to test many different kinds of multi-mode MEMS devices. So far KYEC has succeeded in testing related MEMS devices such as Microphone, gyroscope, acceleration sensor, electronic compass, pressure sensor and will provide cost-effective and high throughput multi-mode testing solutions for 9DOF (Degree of Freedom, DOF), 10 DOF functionalities and Humidity/CO2 sensor in the near future.

A complete range of test platforms are available to support a full range of MEMS test requirements.

|

Vendor |

Model |

Speed (MHz) |

| KYEC in-house designed testing platform | E320 | 100 MHz/200 MHz |

| SPEA | DOT100RM | 50 MHz |

KYEC's MEMS test service solution for IMU sensors is as follows

|

IMU Test System |

|

|

|

|

|

Handler |

SPEA/H3580 |

SPEA/3560 |

HT200M |

KYEC/RD Design |

|

Tester |

DOTI00 |

DOTI00 |

E320 |

E320 |

|

Max Multi-sites |

49 sites |

32 sites |

36 sites |

80 sites |

| Handling | ||||

|

Input |

JEDEC Tray |

Bowl feeder (option) |

Bowl feeder |

Bowl feeder/Waffle Tray |

|

Output |

JEDEC Tray |

T&R (RSU200) |

T&R (All in one) |

T&R (All in one) |

|

Minimum package |

2x2 mm |

2x2 mm |

~1x1 mm |

~1x1 mm |

|

Vision lnspection |

No |

No |

5 sides (option) |

5 sides (option) |

| Motion Stimulus |

RTA 366 |

RTA 330 |

HT Gyro module |

KYE G1 |

| Range: Angle / Angular speed |

450° / ±400 deg/s |

-90° ~ 450° / ±500 deg /s |

-180° ~ +180° / ±200 deg/s |

-90° ~ 450° / ±500 deg/s |

| Accuracy: Rotation angle / Angular speed |

±0.01° / ± 0.05% of full speed |

±0.01° / ± 0.05% of full speed |

±0.05 / ± 0.3% deg/sec |

±0.01° / ± 0.1% of full speed |

|

Temperature range |

-40° ~ 150° |

Room |

Room |

Room |

| Capacity status |

Ready |

Ready in production |

Need to upgrade Gyro module |

Ready in production |

KYEC's MEMS pressure sensor / barometer test solution

| Pressure / Barometer |

|

|

|

|

|

Handler |

SPEA / H3580 |

KYEC / P_Series |

KYEC / PT_Series |

KYEC / PT++_Series |

|

Tester |

DOT100 |

E320 |

E320 |

E320ED |

|

Max. Multi-sites test in parallelism |

49 sites |

64 sites x 4 = 256 sites |

128 sites x 4 = 512 sites |

256 sites x 4 = 1024 sites |

|

Handling |

||||

|

Input |

JEDEC Tray |

Waffle Tray |

Waffle Tray |

Waffle Tray |

|

Output |

JEDEC Tray |

T&R (All in one) |

T&R (All in one) |

TBD |

|

Minimum package |

~2x2mm |

~1x1mm |

~1x1mm |

~1x1mm |

|

Vision Inspection |

No |

5 sides (option) |

5 sides (option) |

5 sides (option) |

|

Tester resource |

DOT100 / 16 slots |

E320 / 23x2 slots |

E320 / 23x4slots |

E320ED /26x4 slots |

|

PE card I/O channel |

768 channels |

1792 channels |

3584 channels |

7168 channels |

|

DPS (Direct power Supply) |

384 channels |

288 channels |

576 channels |

1152 channels |

|

Stimulus for Pressure |

TPSU |

K_CHV1 |

K_CHV2 |

K_CHV3 |

|

Working Range Pressure/Temperature |

30 ~ 400 kPa / -40 ~ 150℃ |

30 ~ 150 kPa / 10 ~ 90℃ |

10 ~ 130 kPa / -20 ~ 90℃ |

30 ~ 200 kPa / -10 ~ 90℃ |

|

Sensor Accuracy Pressure/Temperature |

0.005% of Full scale / ± 0.1℃ |

0.01% of Full scale / ± 0.1℃ |

0.005% of Full scale / ± 0.1℃ |

0.01% of Full scale / ± 0.1℃ |

|

Max. Chamber number |

3 chambers (Test ping pang by each chamber) |

4 chambers + 4 pre-heat chambers |

4 chambers (Test in parallelism for all chambers) |

4 chambers (Test in parallelism for all chamber) |

|

Status |

Ready for Production |

Ready in Production |

Ready in Production |

To be ready in Q3/2019 |

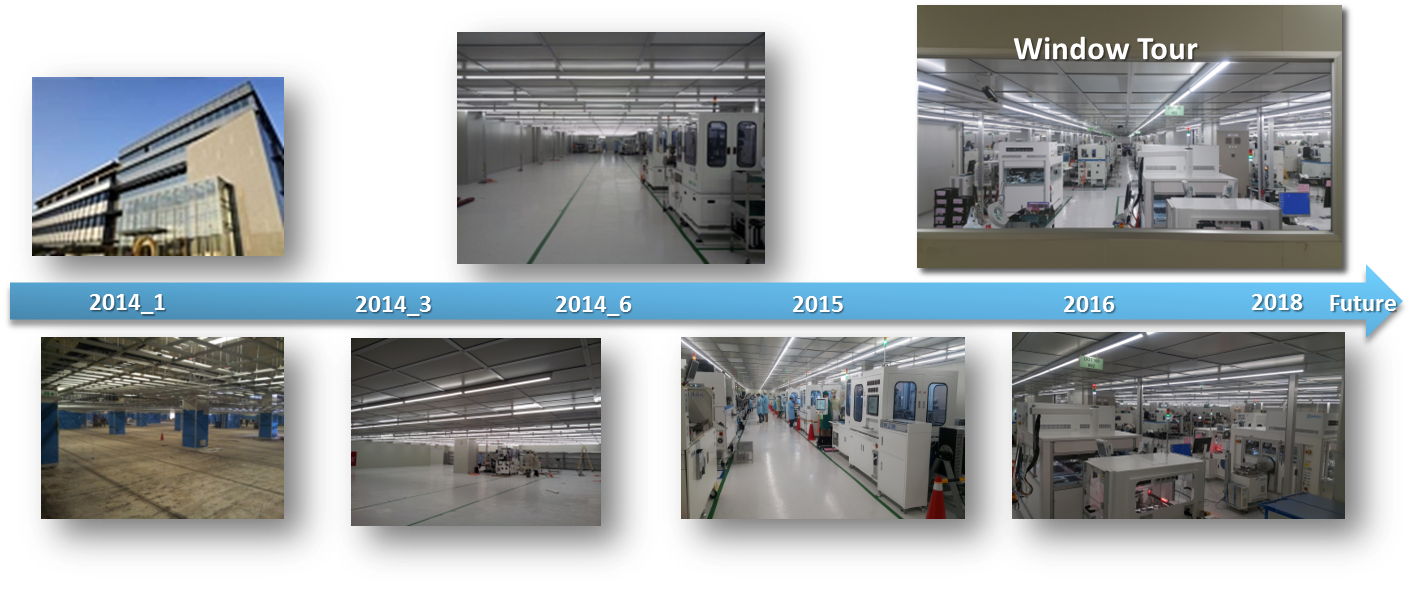

KYEC factory of Electronic Micro-Electro-Mechanical System (MEMS) Product

KYEC Taiwan Tongluo Factory started production in the second quarter of 2014

KYEC's dedicated MEMS test platform

- KYEC builds the Tongluo factory in 2014 and reserves a basement for testing MEMS sensors.

- We have done a lot of work to prepare the test environment for sensor testing.

- Test capacity is growing rapidly.