Policy for Sourcing Conflict Minerals

KYEC’s Supplier Code of Conduct

Policy for Hazardous Substance Process Management (HSPM) System

Supply Chain Sustainable Targets

|

Sustainability KPI |

2024 Target |

Status |

2025 Target |

2026 Target |

|

Conflict Minerals Management: DRC Conflict-Free products |

100% |

Achieved |

100% |

100% |

|

RBA assurance letter recovery rate |

100% |

Achieved |

100% |

100% |

|

SAQ survey completion rate |

100% |

Achieved |

100% |

100% |

|

Sustainability Audit Coverage Ratio of Key High-Risk Suppliers |

100% |

Achieved |

100% |

100% |

Sustainable Value Chain

Supply Chain Regulatory Mechanism

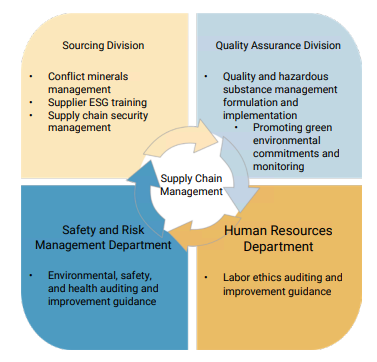

The supply chain management organization operates under the frame work of the Sustainable Development Committee and regularly reports to top management to ensure the implementation of all measures. This management organization includes multiple departments such as the Sourcing Division, Quality Assurance Division, Safety and Risk Management Department, Human Resources Department, which collectively focus on suppliers' social responsibility issues, including environmental protection, labor rights, and health and safety.

Audit Results

KYEC had 815 qualified suppliers in 2024, with 35 being new vendors added during the year. By the end of 2024, annual audits were completed for 66 suppliers, and these suppliers have completed assessments of environmental and social impacts.

We conduct sustainability risk audits in accordance with RBA (Responsible Business Alliance) standards. In 2024, a total of 66 key suppliers were audited, accounting for 8.1% of the total number of first-tier supplier factories. Among these, the number of key high-risk suppliers (defined as suppliers scoring 70% or below in any aspect of the sustainability self-assessment questionnaire or showing non-compliance in sustainability evaluation results) was 16. All 16 of these vendors underwent on-site (online) audits, accounting for 100% of the total number of high-risk supplier factories

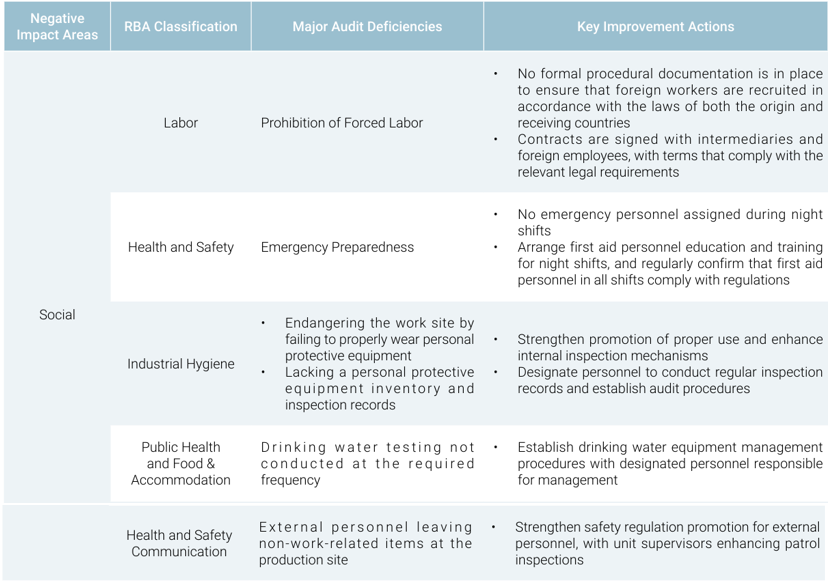

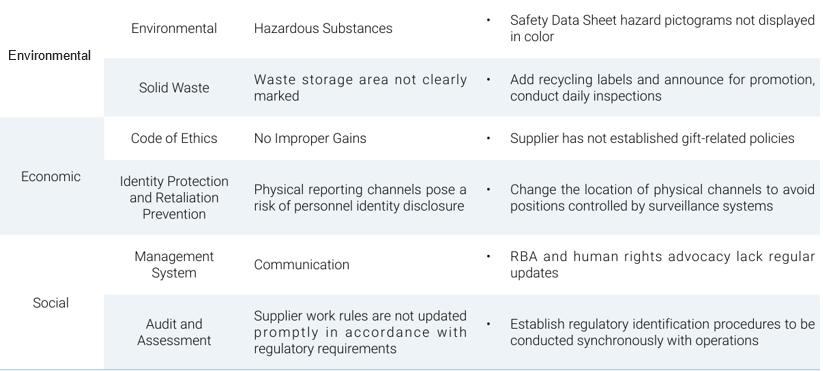

Key High-Risk Supplier Sustainability Audit Results

The Company categorizes issues identified in sustainability audits into two types based on severity and urgency: priority non-conformance items and other non-conformance items. According to the 2024 audit results, no major violations or deficiencies requiring immediate reporting were found among any suppliers. All identified deficiencies have been rectified by suppliers within the specified timeframe, and good progress has been made in improvement measures.

Improvement Measures

In the 2024 audit results, the main types of deficiencies were concentrated in areas such as labor employment, occupational safety, and environmental management, with labor-intensive suppliers being particularly prone to these issues. For deficiencies in ethical code integrity, environmental safety, and other areas, we have adopted time-limited improvement strategies and continue to conduct monitoring and assistance in supplier management. For non-conforming suppliers, we require them to establish monitoring mechanisms, and our supply chain sustainability audit team conducts regular follow-ups through focused guidance and secondary audits to reduce the likelihood of future risks.

- Supplier improvement measures

KYEC’s Supplier Code of Conduct

KING YUAN ELECTRONICS CO., LTD., its subsidiaries (collectively, “KYEC”, “We”, “Us” or “Our”), being a responsible world-class corporate citizen, have taken proactive measures to ensure the highest standards of professional and ethical business conduct. KYEC is committed to implementing sustainable development and social responsibility.

In order to ensure that working conditions in the supply chain are safe, workers are treated with respect and dignity, and business operations are environmentally responsible and conducted ethically, KYEC established this Supplier Code of Conduct ( "Code"). KYEC require our suppliers', contractors', service providers' and subcontractors' (collectively, “Suppliers”, “You” or “Your”) business conducts to strictly comply with this Code as well as laws and regulations of countries/area where suppliers' operations exist with respect to labor, health and safety, environmental, business ethics and the management system. KYEC also encourages suppliers to require their suppliers, contractors, services providers and subcontractors to adopt and comply with this Code. Suppliers' status of compliance with this Code will be one of the considerations for KYEC's evaluation of and decision making on the purchasing.

The provisions in this Code are derived primarily from the Responsible Business Alliance (“RBA”, Formerly EICC) Code of Conduct ,and are in alignment with the UN Guiding Principles on Business and Human Rights, the provisions in this Code are derived from and respect internationally recognized standards including the ILO Declaration on Fundamental Principles and Rights at Work and the UN Universal Declaration of Human Rights.

The Code is made up of five sections. Sections A, B, and C outline standards for Labor, Health and Safety, and the Environment, respectively. Section D adds standards relating to business ethics. Section E outlines the elements of an acceptable system to manage conformity to this Code.The download link of KYEC Supplier Code of Conduct is as below.